- Home

- About Us

- CAPABILITIE

- Products

- > Maternal and Baby Products

- > Kid Toys

- > Pet Toys and Supplies

- > Household Silicone Products

- > Beauty & Care

- > Silicone Rubber Parts

- > Silicone Gift Customization

- > Seal Ring and O-ring

- > Silicone Rubber Sleeves and Case

- > Silicone Rubber Keypad

- > Silicone Strap

- > Pump Valve Rubber Seals

- > Sports & Outdoors

- Solution

- News & Media

- Contact us

Manufacturing

With over 10 years experience in silicone industry manufacturing, and range of technologies at their fingertips, Infaye ensures their clients get the best and high quality product for their needs.

Enjoy the Journey of Silicone Product From Raw Material to Finished Product

Learn how Infaye manage the whole manufacturing process of silicone product and complete your order on budget and on time, batch after batch.

Sampling Prototype

Material Mixing

Bulk Injection

Quality Control

Packaging

Product Design #1

Infaye helps you streamline the process of getting your silicone molding products

beyond the concept stage and into the consumers’ hands.

Mold Making Solution #2

Find our full range of solutions to make your siligel products an optimized reality.

Production #3

Infaye team can assure you that we can understand your requirements well and deal with your project professionally.

Prototype and Molding

CNC machining investment speed up production leadtime

our in-housed dedicated CNC facility workshop and experienced engineer team ensure product developing and molding more Efficient.

an apposite mold design can save cost, the most important is to make sure product comes out with high quality and comply with safety standards.

“We have worked with Infaye for a number of years and have always been impressed with their quality of work. They are real product makers, they add value to the product making process.”

Product Manufacturing Tour Video

Where the world turns bright & colorful

- Design & Manufacturing

- Rubber Silicone Colour Mixing

- Mould Making Solution

- Injection Molding

Design & Manufacturing

Design for Manufacturing is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. DFM involves efficiently designing or engineering an object, generally during the product design stage, this allows a manufacturer to identify and prevent mistakes or discrepancies.

Rubber Silicone Colour Mixing

Silicone Rubber mixing process is one of the determinations of physical and chemical properties of vulcanized rubber. Silicone rubber being mixed and milled with pigment before it is used in a compression moulding process. Time, temperature, and remove from the roller are important elements for mixing.

Mould Making Solution

Mold is one of the most important parts of the injection molding process—we engineer them with the proper design and materials.We also provide mold flow and thermal analysis,ensuring maneuverability.when the right tooling decisions are made,production is optimized,costs are reduced,and quality and customer satisfaction are improved.

Injection Molding

Besides Silicone, we also supply silicone combine with plastic parts product. And injection molding is the most commonly used manufacturing process for the plastic parts. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold.

Silicone Molding Products Manufacturing

The Heart of Silica Molding Performance

3D design

OEM/ODM are welcome. experienced engineer teamhave good command of Rhino3D NURBS, and can and finish 3D drawing base on custom’s requirements and provide solutions.

Prototype

Prototype will be made once layout approved and order confirm. Which allow us to provide visibility and realizability physical sample for touching and checking, and we can modify production size and colors for final production

Mold making

We have our own mold tooling facility instead of out-sourcing, as well as skilled workers can speed up and shorten production lead time.

Silicone mixing

- Silicone rubber raw material is milling under suitable material ratio, pressure and time, convert from solid, tough to soft and flexible.

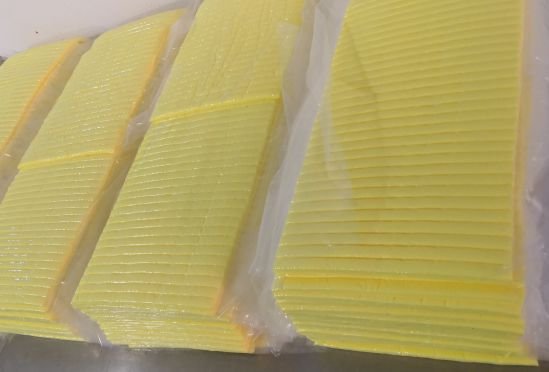

Material Ready

Keep the stripes clean and in place, which is get ready for bulk production

Material cutting

When material flat soft sheet is ready, and it will be cut into many small stripes base on production size & weight, which the stripes can cover into several cavities at one time effectively instead of putting one by one.

Bulk injection

Raw material is injected under suitable temperature, pressure and time, then formed into production by molding .

Oven treatment

All productions will be 100% check and arrange 2nd oven treatment for 6 to 8 hours under 180 to 190 centidegree, which is in order to make our production with enough oven treatment and comply with FDA / LFGB standards.

Production trimmed

Because of parting lines, production will have burrs that needs trimming and cutting after injection.

Quality control

The care and attention put into every one of the products we produced. strict quality control plans translate into dimensional layouts, and material certification for durability

We have the full control over our process, from raw material to trimming to finishes

- Incoming checking, for example, material no. And batch

- Inline checking, such as checking product if lack of material, if oven treatment enough

- Final checking including scratch, dirty, broken, flash, etc.

- Production certification: FDA, REACH, BPA, ROHS, etc.

2nd production check

100% quality control from prototype to volume production.

We have the full control over our every processing. Before packing, our QC team and workers will 100% full check productions. Everything is checked and approved before leaving our factory.

Packing customization

Packing customization:Besides regular polybag packing, we can also provide design for clients’ custom packaging. Such as plastic box, blister, backing card, open box, etc.